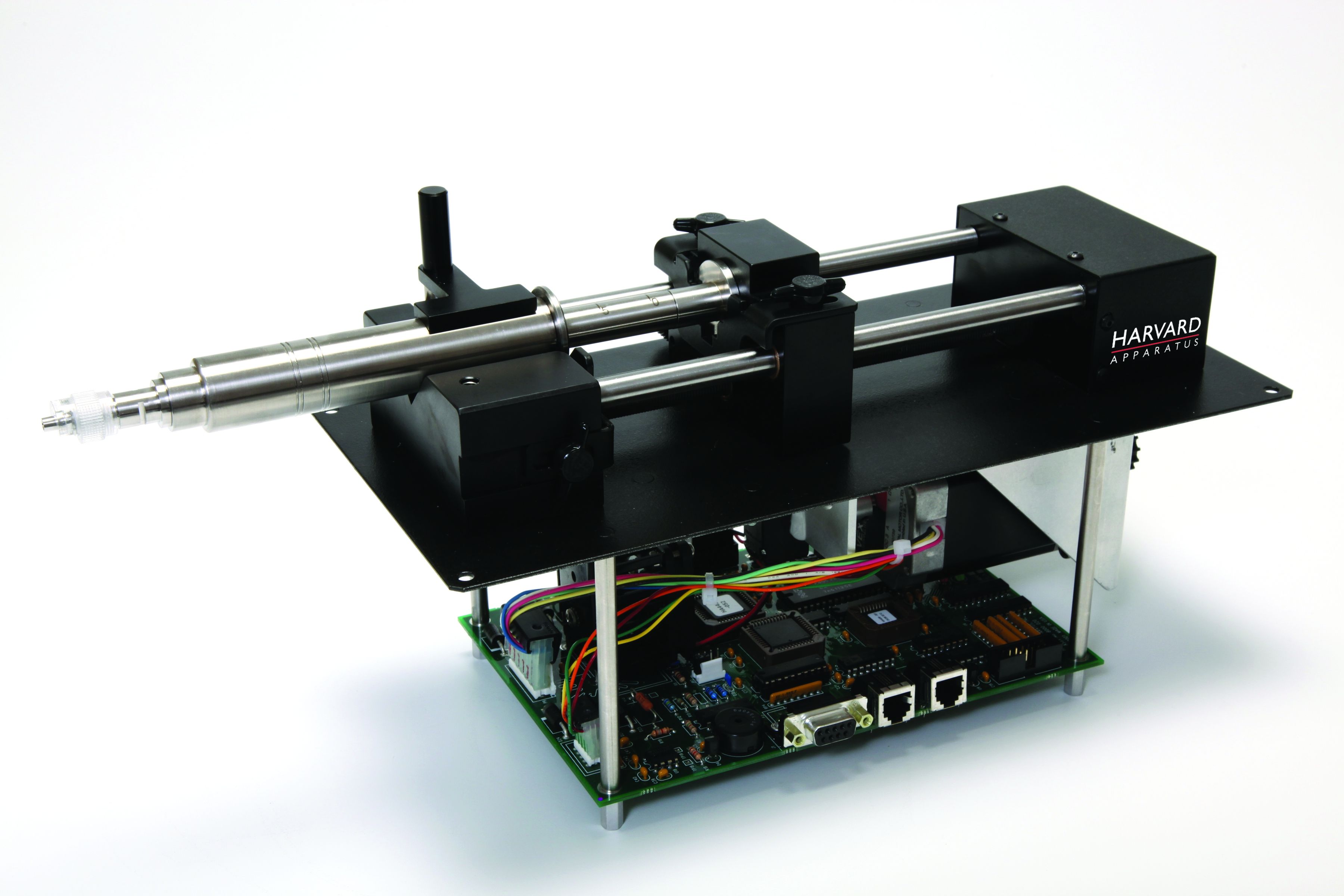

High Pressure OEM Syringe Pump Modules

The High Pressure Syringe Pump Module employs a microcontroller which controls a small step angle stepping motor that drives a lead screw and Pusher Block. Microstepping techniques are employed to further reduce the step angle, eliminating flow pulsation. Data can be entered via an RS-232 connector located on the micro controller. The microcontroller calculates the cross-sectional area of the syringe selected and calibrates the flow rate and volume accumulation. The numerous features of the High Pressure Pump Module result from the use of microprocessor technology.

The High Pressure Syringe Pump Module employs a microcontroller which controls a small step angle stepping motor that drives a lead screw and Pusher Block. Microstepping techniques are employed to further reduce the step angle, eliminating flow pulsation. Data can be entered via an RS-232 connector located on the micro controller. The microcontroller calculates the cross-sectional area of the syringe selected and calibrates the flow rate and volume accumulation. The numerous features of the High Pressure Pump Module result from the use of microprocessor technology.

The High Pressure Programmable Pump Module model provides full programmability along with Infuse/Withdraw capability. This unit is designed to operate inside an enclosure, cabinet, or on top of a bench. The board may be removed for “remote” operation.

Features

- Easy to incorporate legendary syringe pump technology into your equipment

- Ideal high force syringe pump for do-it-yourselfers and OEM equipment designers

- Precisely dispenses volumes at high pressure

- Smooth flow

- Nonvolatile memory

- Three modes of operation:

- Constant flow rate

- Volume dispense

- Programmable

- Quantity discounts available on request

Program Description

The programming functions of this pump provide powerful capabilities for advanced experiments. While in program mode this pump can perform the following tasks at a predetermined time or when prompted by a signal from an external device:

- Start or stop pumping

- Change pumping direction (infuse-withdraw)

- Change flow rates

- pump a precise volume and stop

- Pause operation

- Ramp up or down flow rates

In program mode the above tasks can be linked together into powerful programs to simplify your automation projects.

Functionality

Pressure and Speed

The High Pressure Pump Module can deliver up to 220.82 ml/minute with a single 140 ml syringe. Maximum pressure is dependent on syringe size. Drive produces >200 lb linear force.

Infusion and Refill Rates

Specify independent rates for infusing and refilling. This allows a slow infusion rate then a fast refill.

Target Volume

Specify the volume that is to be infused or refilled. The pump will run at the rate specified until this volume has been delivered when in the Volume mode.

Auto Fill

Auto Fill automatically activates an externally attached solenoid and refills the syringe when it is empty. This permits infusions to be virtually independent of syringe capacity. When set to ‘ON’, the syringe is assumed to be empty. Auto Fill continuously monitors the volume of the syringe according to the volume pumped. When the pump determines that the syringe is empty, the operation in progress is suspended and Auto Fill is activated. The pumping direction is then reversed and the pump runs at the refill rate.

Modes of Operation

(Set for pump mode, can be changed thru RS-232)

- Pump: Runs continuously in the infuse or refill directions until stopped.

- Volume: Runs until a specified volume has been pumped or refilled.

- Program: Pump operates according to specified sequence of instructions.

(Note: All modes interact with Auto Fill)

External Connections User I/O

Allows pump operations to be synchronized with external devices or by a person at a distance from the pump. Connector pins are available to control direction of pump travel to control an external valve for refilling, and for general use. A simple contact closure to ground or TTL level signals may be used for inputs.

RS-232

Multiple pumps can be ‘daisy chained’ together and remotely controlled from a computer or any device communicating via RS-232.

Stall Detection

An optical detector is used to verify expected movement of the motor. If the motor is prevented rfom turning due to jamming or excessive back pressure, the pump will stop.

Program Storage

Programmable model can store up to 4 sets of 9 program sequences for later selection.

Infuse Rate

The Infuse Rate is the rate of pumping while infusing in the Pump or Volume modes.

Target Volume

The Target Volume is the volume that you desire to deliver at the set Infuse or Refill Rate.

This Pump Module is supplied complete with the following components:

- Component Quantity

- Main Unit 1

- Motor/Encoder Extension Cable, 6 ft. 1

- DC Power Extension Cable, 6 ft. 1

- RS-232 Cable 1

| Specifications | 70-2202 |

|---|---|

| # of Syringes | 1 |

| Accuracy | ±0.5 |

| Average Linear Force | 200 lb(90.91 kg) |

| Cable Length | 6 in (15.24 cm) |

| Communications | DC Power 4-pin Header (Friction Lock – Molex or AMP) RS-232 4-pin RJ-11 Telephone Jack User I/O 9-pin D-Sub Female |

| Control Board Mounting Holes | Mounting holes for (4) #6 screws |

| Dimensions, Control Board Mounting L x W | 4.50 x 7.00 in (11.43 x 17.78 cm) |

| Dimensions, Mounting L x W | 11.375 x 5.00 in (28.9 x 12.7 cm) |

| Dimensions, Overall H x W x D | 6.625 x 5.50 x 11.875 in (16.8 x 14.0 x 30.2 cm) |

| Display | Optional 2x20 Line VFD (p/n 2400-235) |

| Drive: Control | Constant Current (Chopper) Drive, 2A per phase (max.), microstepping (from 1/2 to 1/32) |

| Drive: Lead Screw Pitch | 24 threads per inch |

| Drive: Ratio | 2:1 (1:2 optional) |

| Environmental Humidity | 20 to 80% RH non-condensing |

| Environmental Operating Temperature Metric | 0 to +35 C |

| Flow Rate Maximum | 220.82 ml/min |

| Flow Rate Minimum | 0.001 ul/min |

| Keypad | Optional (p/n 2400-252) |

| Motor | 1.8 deg |

| Mounting Holes | Mounting holes for (4) #8 screws |

| Net Weight | 8.5 lb (3.86 kg) |

| Pump Function | Infuse/Withdraw |

| Pusher Travel Rate Maximum | 190.676 mm/min |

| Pusher Travel Rate Minimum | 0.18 mm/min |

| RS-232 | RS-232 |

| Reproducibility | ±0.1 |

| Step Rate Maximum | 416.7 sec/step |

| Step Rate Minimum | 27.3 step/sec |

| Syringe Size Maximum | 140 ml |

| Syringe Size Minimum | 0.5 ul |

| Voltage Range | (+)12 to +40 VDC |